chemical toys Chinese factory

Exploring the Production Process of Chemical Toys in Chinese Factories

Chemical toys, a popular category of children’s playthings, have been a significant part of the toy industry for many years. These toys, which often include items such as Slime, putty, and glow-in-the-dark substances, are primarily produced in Chinese factories. The production process of these toys is a fascinating blend of chemistry, engineering, and manufacturing techniques.

| Number | Products |

| 1 | plasticine |

The journey of a chemical toy begins with the design phase. Toy designers work closely with chemists to create a product that is not only fun and engaging but also safe for children to use. They consider factors such as the toy’s texture, color, and behavior, all of which are determined by the chemical composition of the materials used.

Once the design is finalized, the production process begins in earnest. The first step is the sourcing of raw materials. These materials, which include various chemicals and compounds, are carefully selected based on their safety profiles and the desired characteristics of the final product. For instance, a toy slime might require a specific type of polymer to achieve the desired gooey texture.

The raw materials are then transported to the factory, where they undergo a series of chemical reactions to form the base substance of the toy. This process, known as compounding, involves mixing the materials in precise proportions under controlled conditions. The result is a substance that has the desired properties, such as elasticity, viscosity, or luminescence.

After compounding, the substance undergoes a series of tests to ensure its safety and quality. These tests, which are conducted by trained technicians, check for factors such as toxicity, flammability, and durability. Any batch that fails to meet the stringent safety standards is discarded, ensuring that only safe and high-quality toys reach the market.

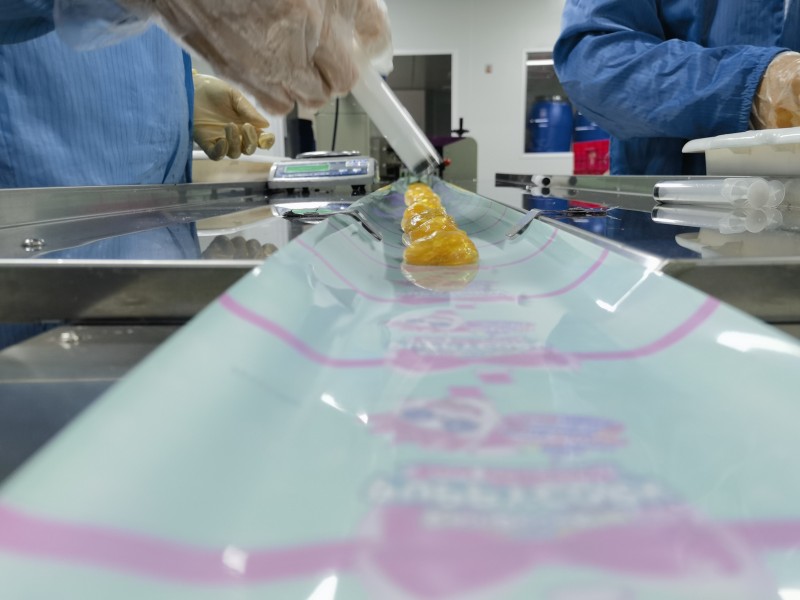

Once the substance passes the quality tests, it is molded into the final shape of the toy. This process, known as casting or injection molding, involves pouring the substance into a mold and allowing it to cool and harden. The molds are designed to create toys of various shapes and sizes, from small figurines to large playsets.

The final step in the production process is packaging. The toys are placed in attractive and durable packaging, complete with instructions for use and safety warnings. The packaged toys are then shipped to retailers around the world, ready to be purchased and enjoyed by children.

Throughout the entire production process, Chinese factories adhere to strict safety and quality standards. They employ trained professionals, from chemists to engineers, who oversee each step of the process and ensure that the final product is safe and enjoyable for children.

In conclusion, the production of chemical toys in Chinese factories is a complex process that involves a blend of chemistry, engineering, and manufacturing techniques. From the initial design phase to the final packaging, each step is carefully controlled to ensure the safety and quality of the toys. Despite the complexity of the process, Chinese factories have mastered the art of producing chemical toys, contributing significantly to the global toy industry.